Empowering Solar O&M with Digital Transformation

A Case Study on Redefining Efficiency and Customer Engagement through a Multiuser Mobile Ecosystem

The Challenge

The solar Operations and Maintenance (O&M) industry is facing a significant challenge. It is a sector split into two halves: Operations, rich in structured data and potential insights, and Maintenance, an area fraught with unstructured, and therefore unoptimized, data. As a result, growth ambitions were being hindered, and scaling was near impossible.

Compounding this challenge was a rising labor cost issue. Despite falling hardware costs, the increasing labor expenses were offsetting these savings, leading to an overall increase in per-megawatt cost. In fact, labor costs were escalating faster than hardware costs were decreasing, creating a stark need for a transformative solution.

The Solution

To confront these challenges head-on, our team envisioned a future where workforce management and operations were integrated, data-driven, and customer-centric. The multiuser mobile ecosystem was introduced, leveraging digital twin technology, IoT, and wearable devices to provide a holistic view of the field situation in real time.

This ecosystem allowed for real-time customer notifications, appointment confirmations, traffic delay alerts, and a FedEx-like experience for tracking technician arrivals. In addition, it allowed for instant sharing of photos and data from customer locations, as well as a two-way communication channel where customers could push information to technicians directly.

Moreover, the system allowed for fast and accurate quoting for customers. If a quote was below a set threshold - say $700 - the work could proceed immediately. If it was above, the system would request an on-demand approval from the customer, keeping them informed and in control at all times.

The digital twin technology, coupled with IoT and wearables, also significantly streamlined the warranty claims and Return Merchandise Authorization (RMA)

The Results

The implementation of this revolutionary multi-user mobile ecosystem led to significant improvements in the overall performance of the solar O&M business.

Reduced Operational Costs: The integration of structured data into the maintenance organization led to operational efficiencies and cost reductions. Labor costs were managed more effectively, helping to balance out the rising labor expense issue.

Efficient Dispatching: With real-time data and intelligent allocation of resources, dispatching became more efficient. The FedEx-like experience provided customers with transparency and control over their appointments.

Closer Customer Intimacy & Faster Up-selling: The two-way communication channel and on-demand approval system fostered a stronger relationship with customers, increasing trust and satisfaction. This, in turn, resulted in faster up-selling and increased revenues.

Raising Growth Ceiling Efficiently: The newfound ability to scale effectively and efficiently broke down previous growth barriers, allowing the business to expand at a faster rate than ever before.

Transforming Reactive Maintenance into Preventive Maintenance: Leveraging data analytics, potential maintenance issues could be identified before they became problems, shifting the focus from reactive to preventive maintenance.

Conclusion

This case study showcases the transformative power of digital twin technology, IoT, and wearables in the solar O&M sector. By integrating these technologies into a cohesive, data-driven system, businesses can overcome existing challenges, streamline operations, and accelerate growth in a cost-effective manner.

The Customer Reporting View

Integral to the innovative ecosystem is the customer reporting view, a comprehensive, real-time, interactive dashboard that provides the customer with an unprecedented level of transparency and control.

Asset Health Scoring

At the heart of the customer reporting view is the Asset Health Scoring. This feature leverages the power of data analytics to present customers with a clear, easy-to-understand 'score' representing the health of their solar assets based on completed and ongoing maintenance work orders.

For those customers who are technically inclined, the system provides a 'drill-down' feature. This feature allows them to dive deeper into the specifics of their maintenance results, gaining insight into the precise work that's been done and how it affects their overall asset health.

FedEx-like View of Maintenance Tech

Mirroring the tracking capabilities of FedEx, our system provides real-time updates on maintenance technicians. Customers are informed when a "Maintenance tech will arrive tomorrow to do x between 9am -12pm," when the "Maintenance tech is en route," and when the "Maintenance tech is on site." This level of transparency puts the power back into the hands of the customer, allowing them to plan their day accordingly.

Two-Way Communication

Customers can also send notes to the maintenance technician in advance through the platform. Requests for custom jobs like "Clean something for cosmetics," or "Do this upgrade," can be communicated directly, ensuring their needs are fully understood and met.

Fast Quoting and Approval

The mobile ecosystem also provides the ability for fast quoting. If a repair costs less than $700, the technician can proceed immediately. For repairs that exceed this threshold, a quote is generated and sent to the customer for approval. This process occurs in real-time, right on the customer's device, allowing for immediate responses and minimized downtime.

Three-Way Call Feature

Lastly, for complex situations, the system facilitates a three-way call between the customer, the sales representative for a seamless customer experience, and the technician for technical details. This feature ensures that everyone is on the same page and that the customer is comfortable with the proposed solution.

This customer-centric approach, combined with the power of digital twin technology, IoT, and wearables, not only empowers customers but also fosters trust, leading to improved customer satisfaction and loyalty.

Key Features Overview

Overview Section

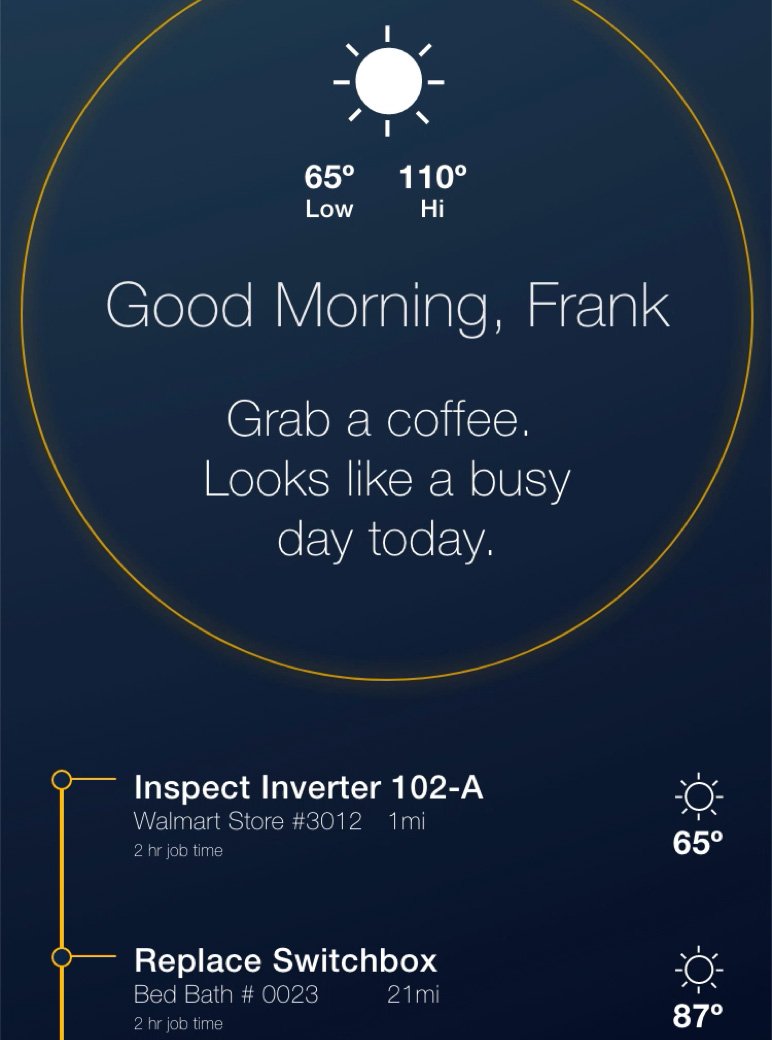

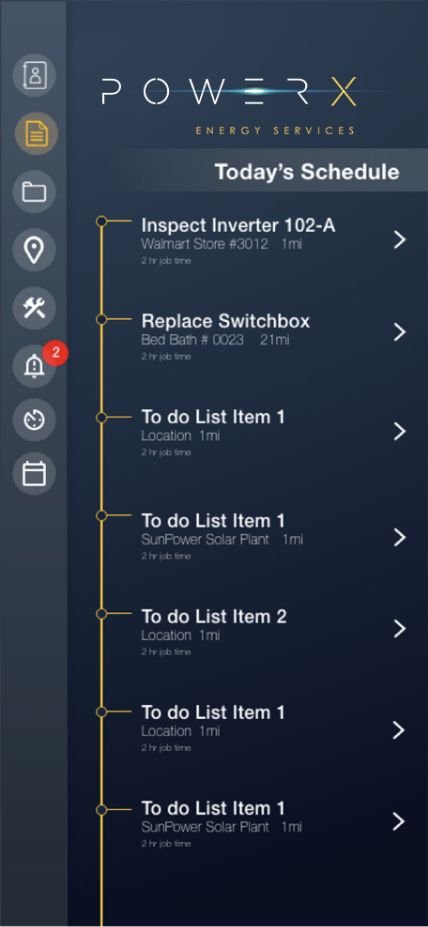

Daily Schedule: Manage and view all scheduled tasks and appointments for the day.

All Tools & Work Orders: Access all necessary tools and view every work order in the system.

All Equipment: View and manage all equipment involved in the day's operations.

All Team Members: Keep track of every team member and their respective roles and assignments.

Geographies & Routes: Visualize the different work locations and the most efficient routes to get there.

Estimated Time & Effort: See estimates of how long each task will take and the effort required.

Ability to Make Edits: Modify schedules, assignments, routes, and more as needed.

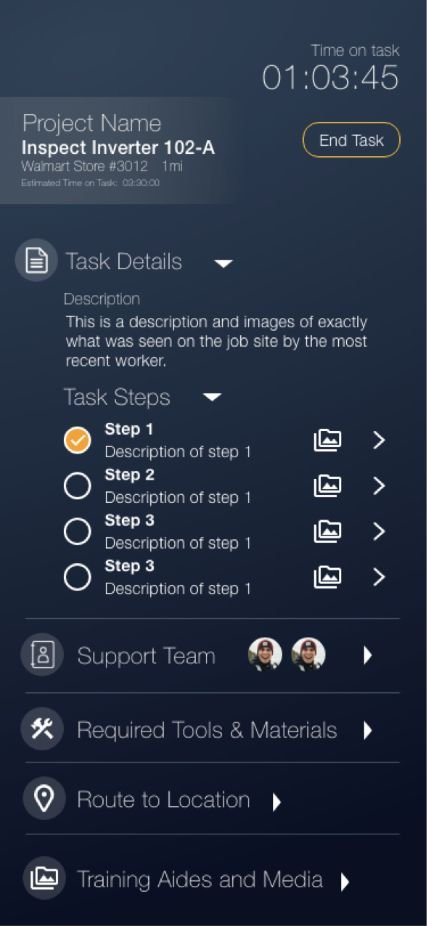

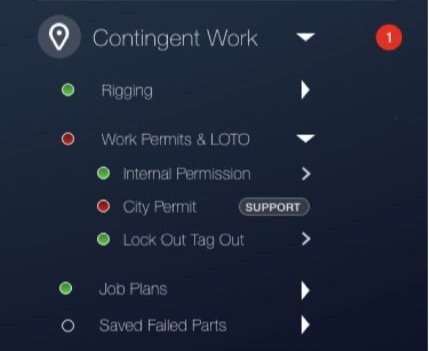

Work Order Section

Job Briefs: Access concise summaries of each job and its requirements.

Safety Analysis & Mitigation Plans: Review safety protocols and potential hazards, along with plans to mitigate any risks.

Review Contingent Work: Access and review necessary work permits and LOTO (lockout/tagout) procedures.

Rigging: Understand the rigging requirements for each job.

Job Plans: Detailed plans of each job's requirements and steps to completion.

Location: See where each job is located.

Review Photos and Reference Docs: Access photographic documentation and any necessary reference materials.

Confirm JHA: Confirm the Job Hazard Analysis and move to execute the work order.

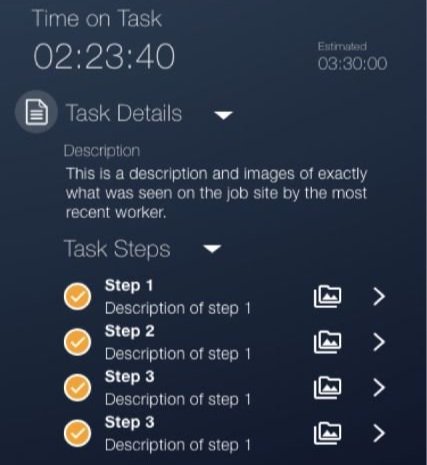

Execute Section

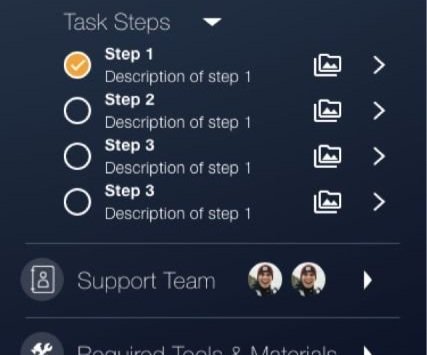

Work Steps: Detailed steps to complete the work order.

Just-in-Time Training Aids: Access to training materials right when they're needed.

Remote Work Support: Support for workers in the field, including live communication and remote troubleshooting.

Collaborative Team & Exception Mode: Ability to work collaboratively and handle exceptions effectively.

Photos & Videos: Capture and share images and videos of the work as it progresses.

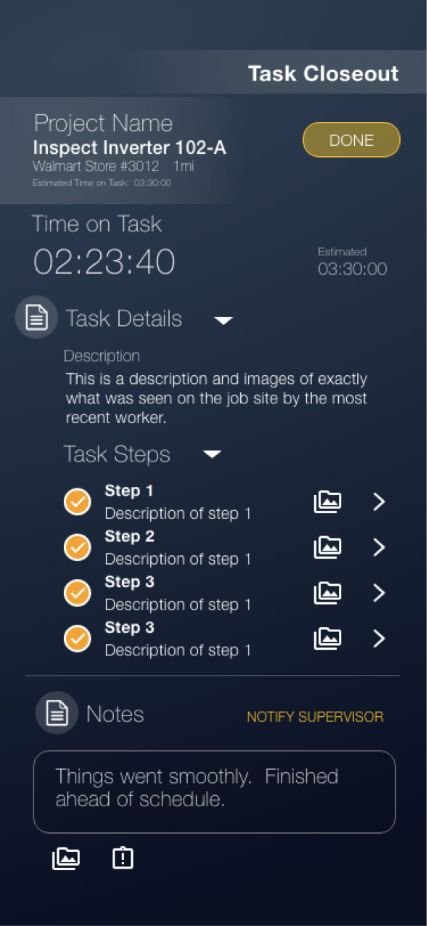

Close Out Section

Edit to Steps and Job Plans: Make necessary edits to job plans and steps based on the work completed.

Upload & Videos for As Found As Left Conditions: Upload photos and videos documenting the condition of the site before and after the work.

Estimate vs Actual Data Comparison: Compare the estimated time and effort to the actual time and effort spent.

Smart Incident Reporting for Problem Identification: Quickly and easily report incidents and identify potential problems.

Automatic Work Order Closeouts: Work orders are automatically closed out when the job is complete.

Analytics and Improvement Opportunities: Analyze performance and identify opportunities for improvement.

Upload for Next Work Order: Prepare for the next work order by uploading all necessary information and materials.